Suspended loads are objects that are lifted and supported above ground level. They can be found in many different workplaces, such as construction sites, warehouses, and factories. When working with suspended loads, it is important to understand the risks involved and take steps to prevent accidents.

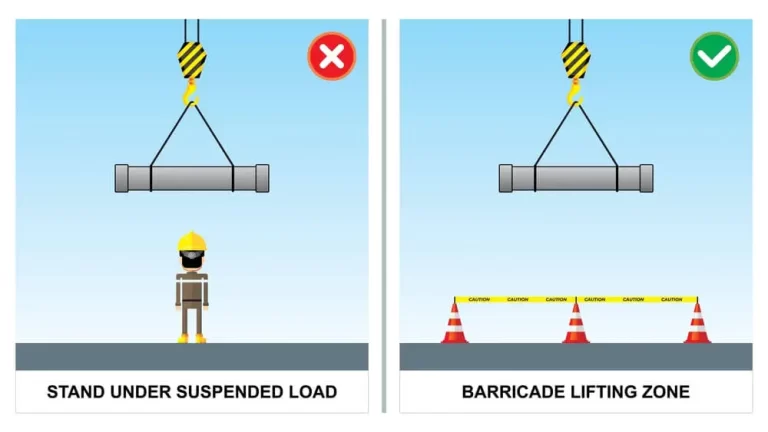

One of the biggest risks associated with suspended loads is dropped objects. Dropped objects can cause serious injuries, even death. The fall/drop zone is the area underneath a suspended load where objects could fall. It is important to identify the fall/drop zone and keep people out of it whenever a suspended load is present.

The different types of suspended loads

There are many different types of suspended loads, but some of the most common include:

- Materials handling equipment: This includes forklifts, cranes, and hoists. These are used to lift and move materials in a variety of industries, such as construction, manufacturing, and warehousing.

- Construction materials: This includes beams, girders, concrete slabs, and other materials used in construction. These materials are often suspended from cranes or hoists during construction.

- Industrial machinery: This includes motors, generators, pumps, and other machinery used in industrial settings. These machines are often suspended from overhead beams or gantries for maintenance or repair.

- Shipping containers: These are large containers used to transport goods by sea, land, or air. Shipping containers are often suspended from cranes during loading and unloading.

- Pallets of goods: These are platforms used to transport goods in a warehouse or distribution center. Pallets of goods are often suspended from forklifts or hoists during transportation.

- Vehicles: Vehicles, such as cars, trucks, and buses, can also be suspended from cranes or hoists for maintenance or repair.

These are just a few of the many different types of suspended loads. The specific types of suspended loads that are used in a particular workplace will depend on the industry and the activities that are performed in that workplace.

The hazards associated with suspended loads

Wind gusts: Wind gusts can cause suspended loads to sway or swing, increasing the risk of a fall.

Collisions: Suspended loads can collide with people or objects if they are not properly controlled. Collisions can cause serious injuries, even death.

Electrical hazards: Suspended loads can come into contact with electrical lines, which can cause electric shock or fire.

Operator error: Human error is a factor in many accidents involving suspended loads. Operators must be properly trained and follow safe working practices.

Dropped objects: Suspended loads can fall if the lifting equipment fails, the load is not properly secured, or the load is too heavy for the equipment. Dropped objects can cause serious injuries, even death.

Poor visibility: Poor visibility can make it difficult to see suspended loads, increasing the risk of a collision.

Slings and rigging failures: Slings and rigging are used to secure suspended loads. If these components fail, the load can fall, causing serious injuries or death.

The importance of the fall/drop zone

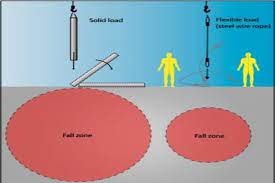

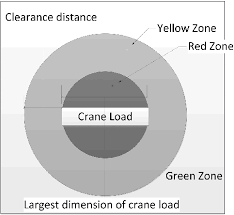

The fall/drop zone is the area underneath a suspended load where objects could fall. It is important to identify the fall/drop zone and keep people out of it whenever a suspended load is present. The size of the fall/drop zone will depend on the weight and size of the load, as well as the height at which it is suspended.

The fall/drop zone is important because it can help to prevent accidents involving dropped objects. If people are working or walking in the fall/drop zone, they could be injured if a load falls. By keeping people out of the fall/drop zone, we can help prevent accidents and injuries.

How to identify the fall/drop zone

- To identify the fall/drop zone, you can use the following steps:

Step 1: Determine the weight and size of the load. The heavier and larger the load, the larger the fall/drop zone will be.

Step 2: Determine the height at which the load is suspended. The higher the load is suspended, the larger the fall/drop zone will be.

Step 3: Calculate the radius of the fall/drop zone. The radius is the distance from the load to the point where objects could fall.

The following formula can be used to calculate the radius of the fall/drop zone:

Radius = (Weight of load x Height of load) / 2For example, if a load weighs 100 pounds and is suspended 10 feet above the ground, the radius of the fall/drop zone would be 50 feet.

Step 4: Mark the fall/drop zone with cones, ropes, or other barriers. This will help to keep people out of the area and prevent accidents.

It is important to note that the fall/drop zone can change depending on the circumstances. For example, if the wind is blowing, the fall/drop zone may be larger. It is always best to err on the side of caution and keep people out of the area until the load is secured and the danger of a fall has passed.

Here are some additional tips for identifying the fall/drop zone:

- Consult with a qualified safety professional.

- Consider the specific hazards of the workplace.

- Be aware of the potential for changes in the fall/drop zone.

- Take steps to protect people from the hazards of dropped objects.

By following these tips, you can help to identify the fall/drop zone and prevent accidents involving dropped objects.

Best practices for working with suspended loads

Here are some best practices for working with suspended loads

- Always use the right equipment for the job. The equipment must be properly rated for the weight and size of the load. It must also be in good condition and properly maintained.

- Plan and execute lifts carefully. This includes conducting a risk assessment, selecting the right equipment, and following safe working practices.

- Train employees on safe working practices. This includes how to identify and mark the fall/drop zone, how to use the lifting equipment safely, and how to avoid accidents.

- Inspect equipment regularly. This will help to identify any potential problems before they cause an accident.

- Keep people out of the fall/drop zone. This is the area underneath a suspended load where objects could fall. Even if people are wearing personal protective equipment (PPE), they could still be injured by a dropped object.

- Use safety equipment, such as hard hats, safety glasses, and fall protection. This can help to protect people from injuries if an accident does occur.

- Never work under a suspended load. This is the most important safety rule to follow.

- Do not overload the equipment. Overloading the equipment can cause it to fail, which could result in a fall.

- Make sure the equipment is in good condition. Inspect the equipment before each use and report any problems to your supervisor.

- Follow the manufacturer's instructions. The manufacturer's instructions will provide important safety information for using the equipment.

- Be aware of the weather conditions. Wind gusts can cause suspended loads to sway or swing, increasing the risk of a fall.

- Be alert and aware of your surroundings. Do not let distractions take your attention away from the task at hand.

By following these best practices, you can help to prevent accidents involving suspended loads and keep yourself and others safe.

Here are some additional tips:

- Use a tag line to control the load during the lift.

- Make sure the load is properly secured before lifting it.

- Use a signal person to communicate with the operator of the lifting equipment.

- Do not lift loads that are too heavy or too large.

- Be aware of the overhead clearance when lifting loads.

- Do not lift loads near power lines.

- Be aware of the weather conditions and avoid lifting loads in windy conditions.

By following these tips, you can help to ensure the safe handling of suspended loads.

Safety products that can be used when working with suspended loads

CHOOSE YOUR SAFETY WISELY

If you have any question or require further information, please do not hesitate to contact us at anytime.

(+91) 96031-66448; 98851-49412

Contact with our sales team now!